Fujikura 42S series of fiber optic fusion splicers

Brief description of the series

The inexpensive Japanese Fujikura 42S series of fusion splicers is ideal for access networks, PON, FTTx, SCS and local fiber optic communication lines. All splicers in this series align fibers using active (moving) V-grooves, which provides excellent characteristics: average splice losses are 0.03 dB for single-mode fiber and 0.01 dB for multimode. Fujikura 42S series splicers are unpretentious and reliable, they operate stably at low temperatures, heat, humidity and wind. The service life even in the harshest conditions exceeds 10 years.

The Fujikura 42S series includes three models that differ in cleaver and target region. The Fujikura 42S Plus model (set) comes with an automatic Bluetooth cleaver CT50 and additional accessories. The Fujikura 42S Standard model (set) comes with a classic cleaver CT16. The Fujikura 45S model is designed for the American region and is not sold or serviced in Ukraine. For detailed differences between the models in the series, see the interactive table. A full description of all characteristics can be downloaded below on this page in the Documentation section.

All models of the series

The Fujikura 42S series consists of three models, shown in this interactive table. To see all the characteristics of certain models, add them to the comparison.

| Model |

Splice loss SM

|

Splice loss MM

|

Splice time

|

Heat shrink time

|

Battery life

|

Electrode life

|

Cleaver included

|

|---|---|---|---|---|---|---|---|

|

Novelty

Top sales

|

0.03 dB | 0.01 dB | 6 sec | 16 sec | 230 splices | 6 000 splices | Fujikura CT50 |

|

Novelty

|

0.03 dB | 0.01 dB | 6 sec | 16 sec | 230 splices | 6 000 splices | Fujikura CT16 |

|

Recommended replacement:

Fujikura 42S Plus

|

0.03 dB | 0.01 dB | 6 sec | 16 sec | 230 splices | 6 000 splices | Without a cleaver |

High quality splicing

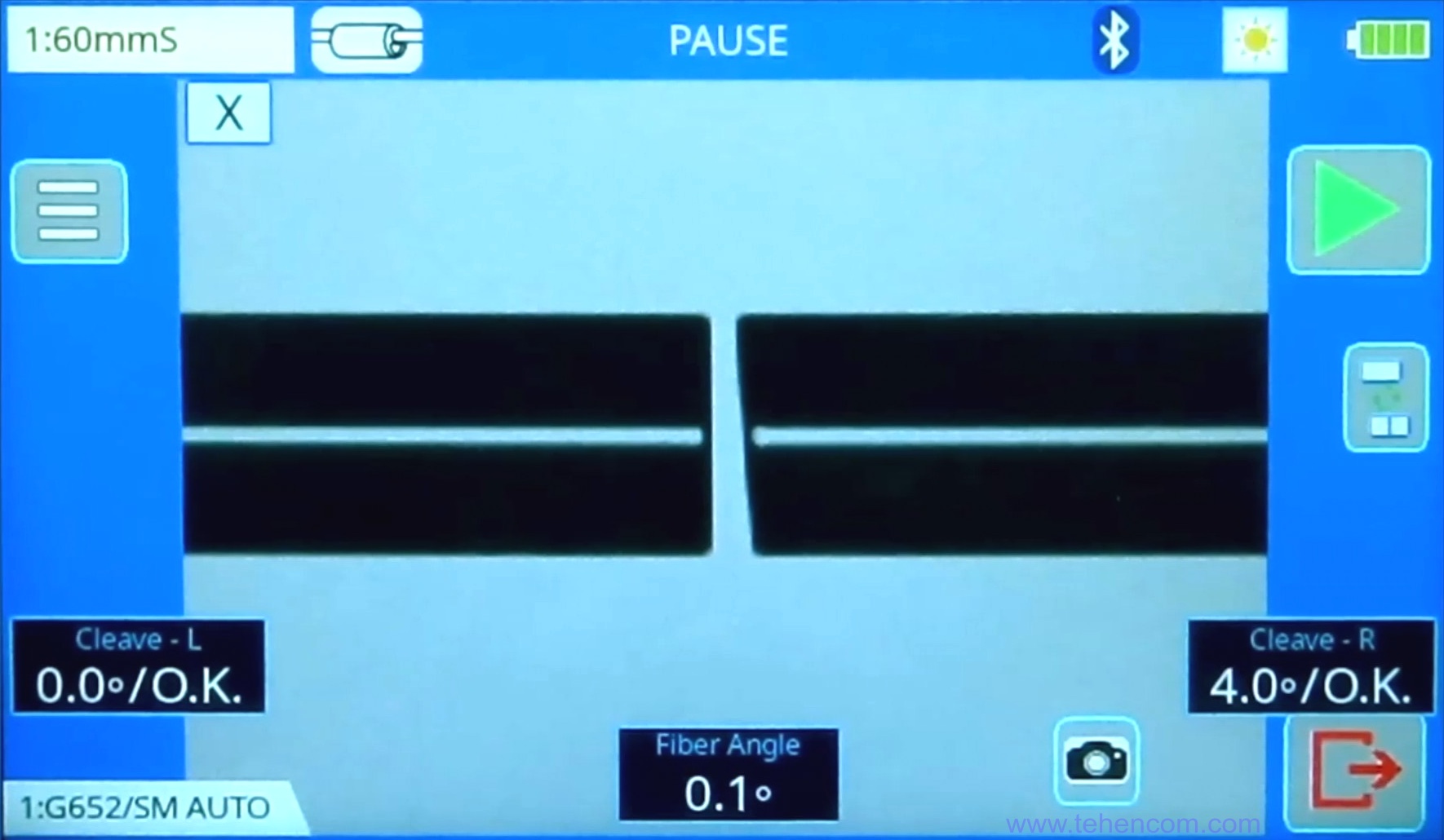

All Fujikura 42S series splicers are equipped with Active Fusion Control technology. This technology ensures high quality splicing under changing environmental conditions, different degrees of electrode wear and large fiber cleavage angles. This screenshot shows a pair of fibers just before splicing, the right fiber has a poor cleavage angle (4 degrees).

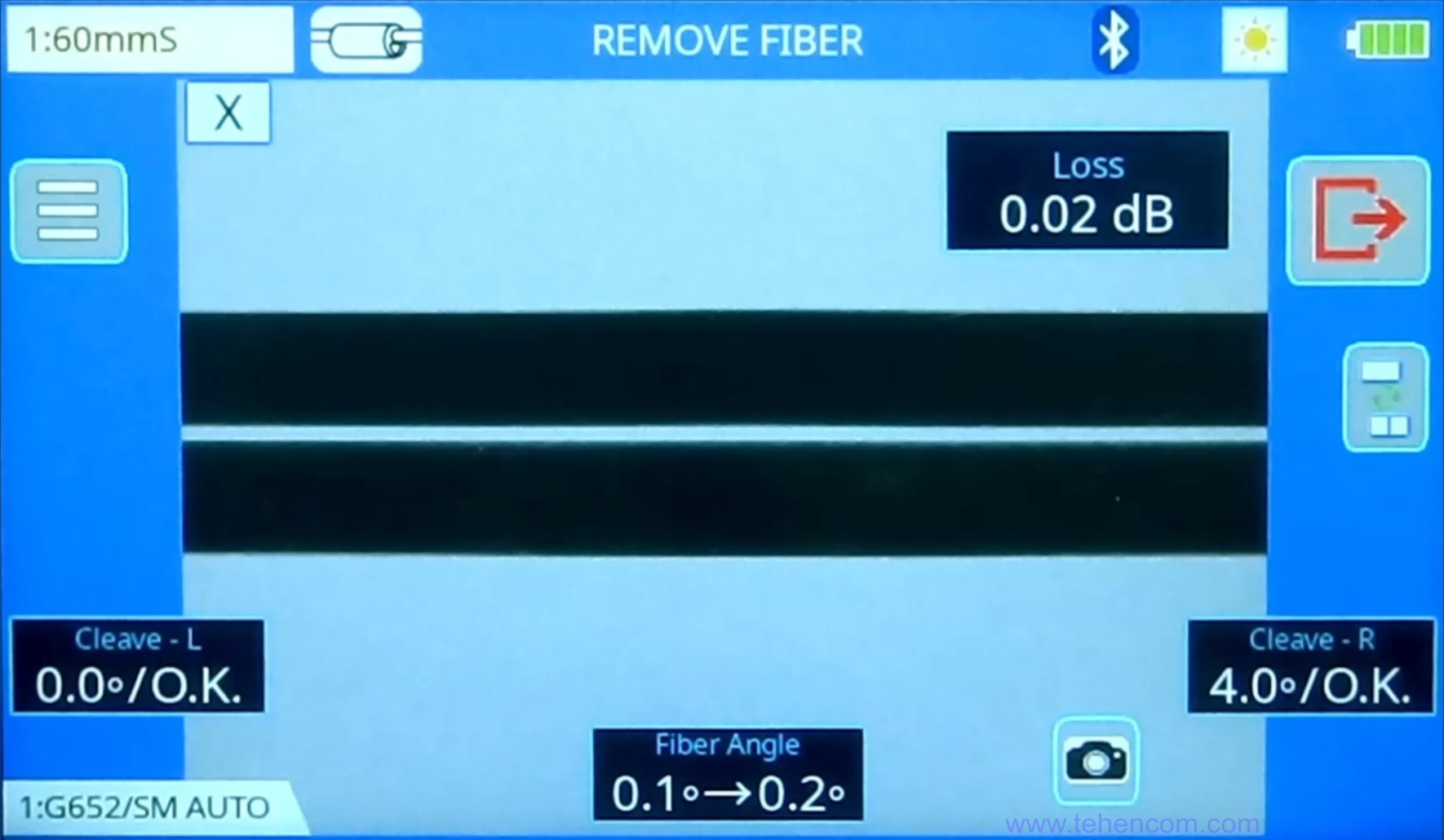

Active Fusion Control technology analyzed fiber cleavage angles and adjusted splicing parameters to compensate for the impact of poor cleavage on the right fiber on the resulting losses. As you can see, the estimated loss after splicing was only 0.02 dB.

Fujikura 42S series fusion splicers analyze arc brightness directly during the splicing process, adjusting its power and duration, which helps compensate for the impact of electrode wear and changing environmental conditions. Also, arc brightness analysis helps the machine more accurately calculate the losses in the splice joint, which are shown on the screen immediately after splicing.

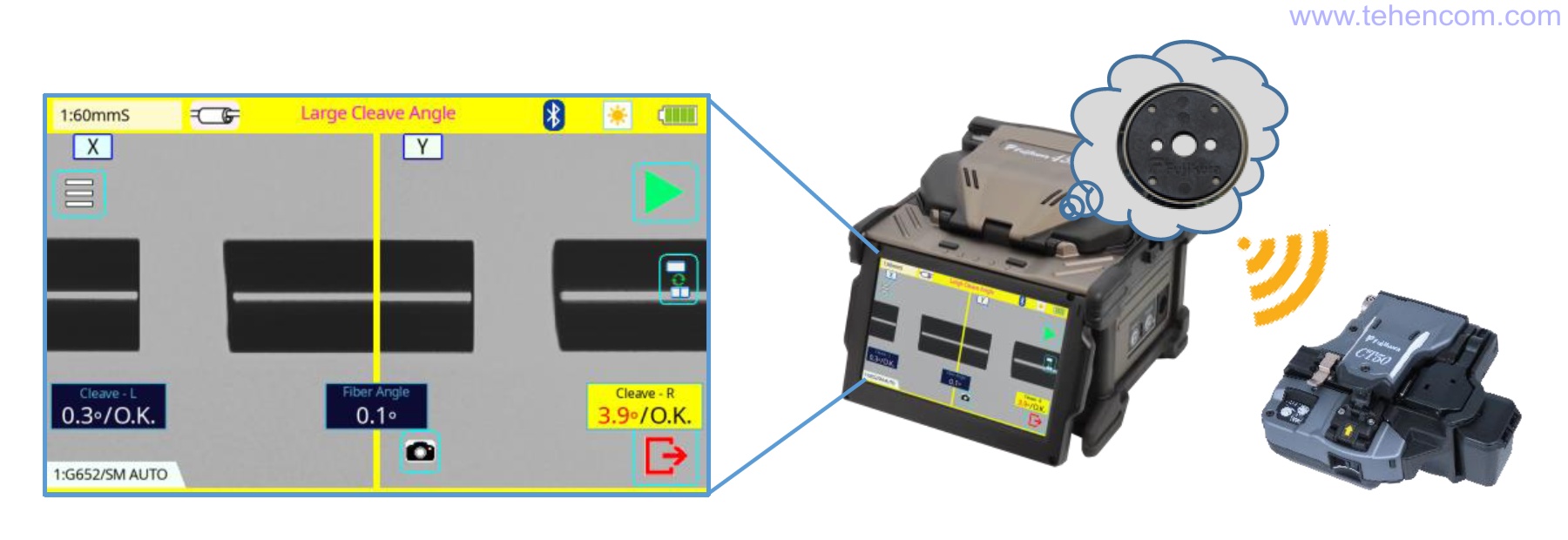

Controlling the cleaver

Using Bluetooth, one or two Fujikura CT50 automatic cleavers can be connected to the Fujikura 42S series splicers. After the first pairing of the splicer and the cleaver, the devices remember the settings and their connection is automatically restored each time they are turned on. This function allows the splicer to keep statistics on the number of fiber cleavages at each blade position, and also automatically rotate the cleaver blade to the next working position based on the analysis of the cleavage angle and its shape.

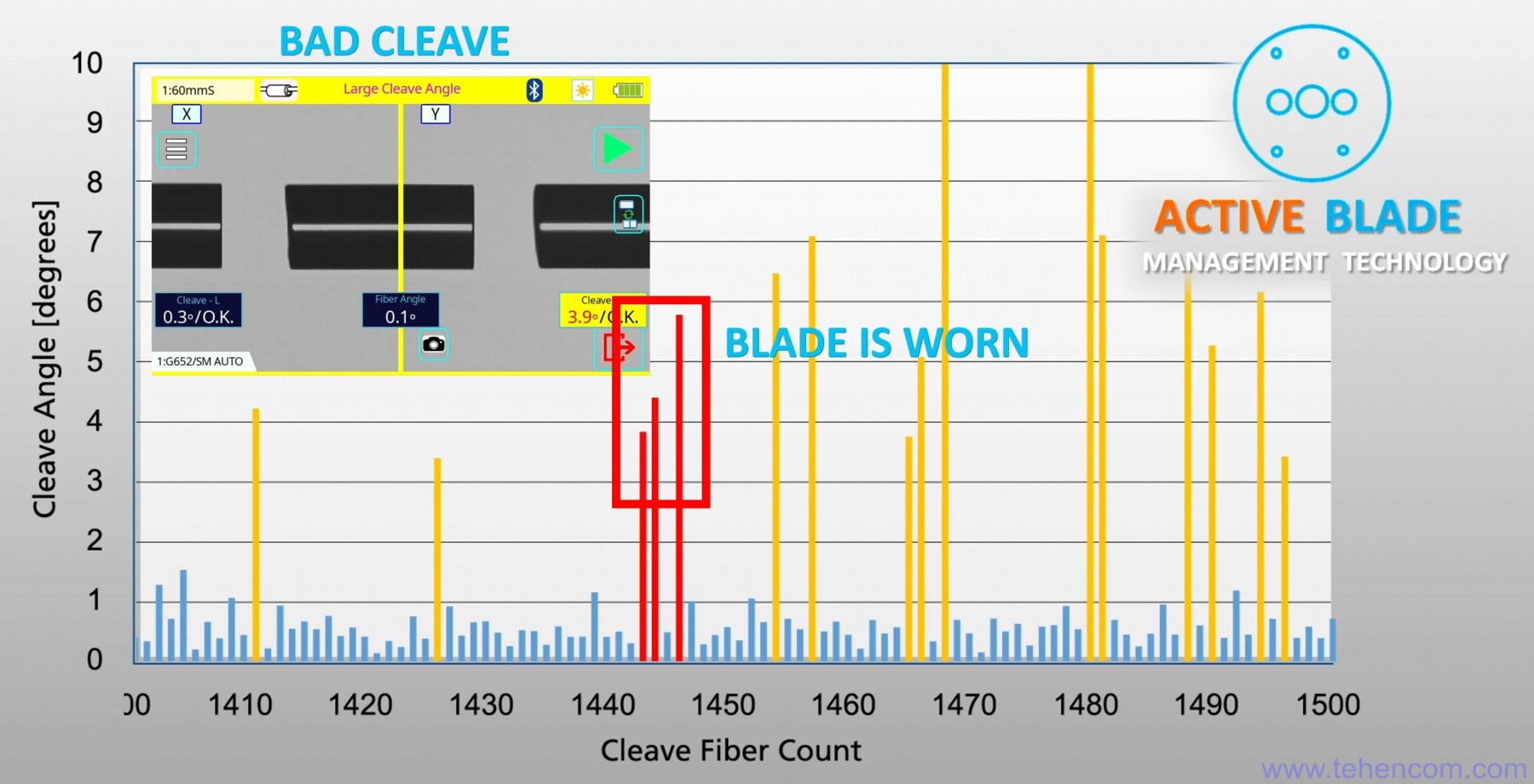

As the cleaver blade wears, the fiber cleavage angle and shape begin to deteriorate. This graph shows typical statistics for the occurrence of bad cleavages as a particular blade position wears. The horizontal axis shows the number of cleavages made, and the vertical axis shows the angle of each cleavage. Bad cleavages are marked with yellow and red vertical lines.

Regular occurrence of a large cleavage angle (3.9 degrees on the right fiber in the screenshot below) or an uneven cleavage shape is a sure sign of wear of the current position of the blade or its contamination. The splicer continuously analyzes both indicators and, when necessary, automatically transmits a command to the cleaver to turn the blade to the next working position. If you want to decide for yourself when to turn the blade, you can switch the automatic rotation to a simple hint in the splicer settings.

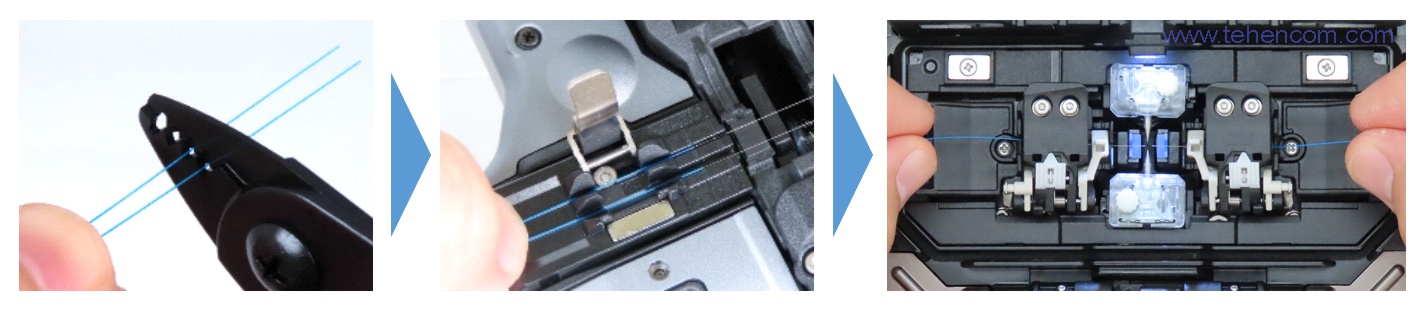

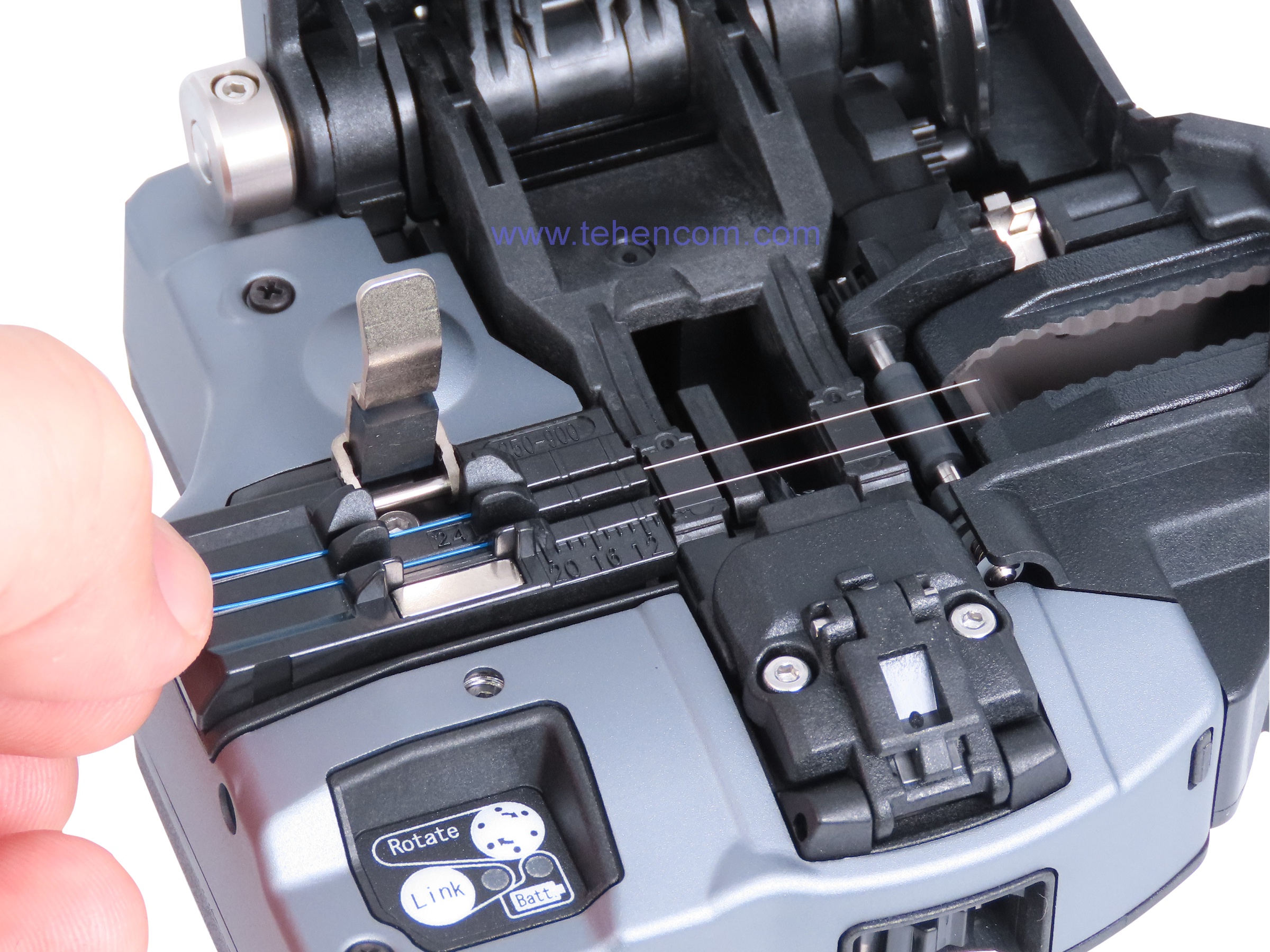

Working with two fibers

When using Fujikura 42S series fusion splicers, you can strip, cleave and install two optical fibers into the splicer at once. For this purpose, the Fujikura SS05 stripper contains two identical holes for fibers with a protective coating diameter of 0.25 mm. The Fujikura CT50 cleaver with an AD-16A setting plate can simultaneously cleave two fibers at once. And the design of the clamps of the machine allows you to close them in one movement by simply pressing your fingers on their edges.

This photo shows the Fujikura CT50 automatic cleaver with the AD-16A setting plate, which holds a pair of fibers in a 0.25 mm buffer. They can be cleaved in one motion and immediately transferred to the splicer. This approach saves a lot of time.

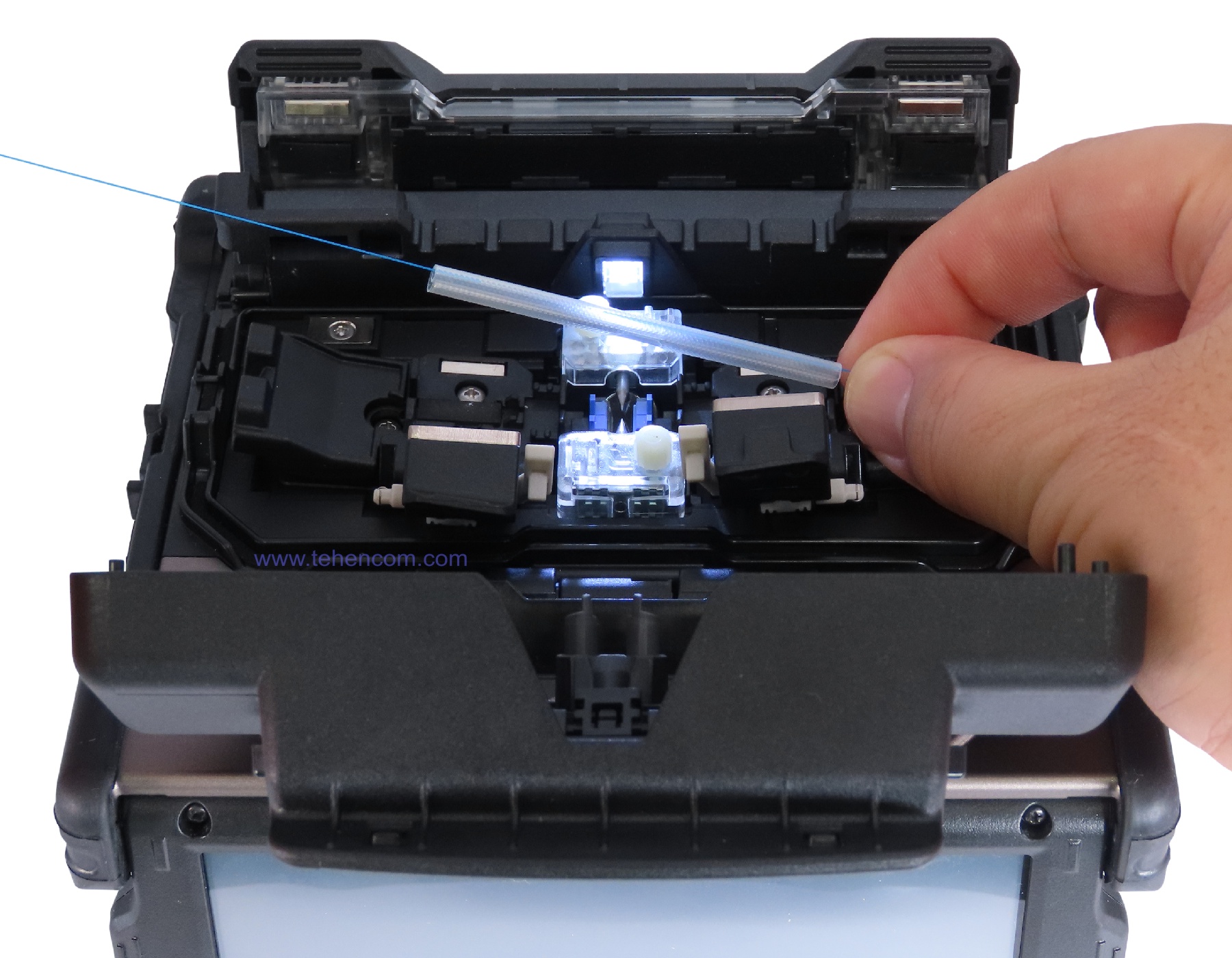

This photo shows a pair of optical fibers that were cleaved and installed in a fusion splicer in one motion. The splicer's clamps can be closed without touching them, simply by simultaneously pressing the pads located at the edges of the clamps with your fingers.

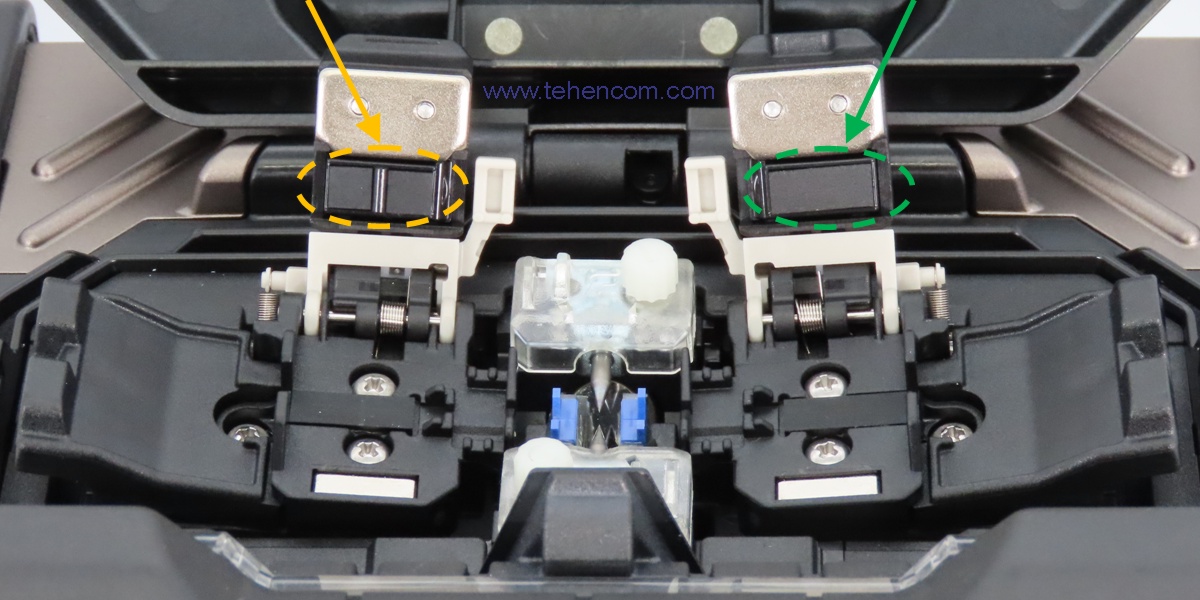

Universal clamps

Fujikura 42S series splicers use universal CLAMP-S35A clamps, which are suitable for most types of fiber optic cladding: 0.25 mm protective varnish, 0.9 mm pigtails (regular buffer), patch cords in 2 and 3 mm cladding, Drop Cable and other types. For comfortable work with pigtails in a loose 0.9 mm buffer, a special modification of clamps with increased clamping force is produced: CLAMP-S35B. These additional clamps are included in the Fujikura 42S Plus kit.

The clamps of the splicer are fixed with one screw and are easily removed. For example, you can leave one universal clamp, and install the second clamp for working with pigtails in a loose buffer. This photo shows just such a configuration. On the right is installed a standard universal clamp CLAMP-S35A, and on the left a clamp for a loose buffer CLAMP-S35B, on which you can see an additional protrusion that increases the pressure on the buffer, which does not allow it to slip.

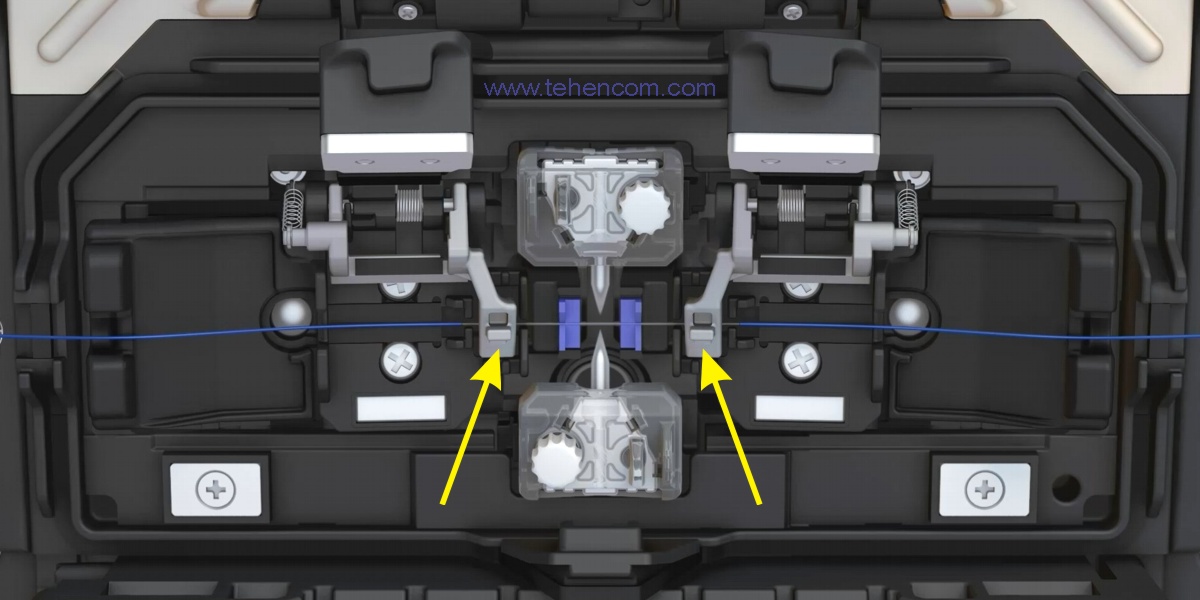

The Fujikura 42S clamps have small additional fiber retainers built into the design. After splicing, when the clamps are opened, these retainers stay in place and gently hold the spliced fiber so that it does not pop out. When you start lifting the fiber to center the heat shrink sleeve, the retainers lift up easily.

These additional retainers can be attached and detached to the corresponding clamp at any time. It is possible to make it so that after opening the clamps only the left or only the right fiber remains fixed, or turn off this function altogether.

There are two mechanical switches on the edges of the splicer cover that can be used to make the fiber optic clamps open immediately when the cover is opened. The switches are independent of each other, so you can open both clamps, just one clamp, or leave the clamps closed.

The distance from the edge of the clamp to the electrodes of the Fujikura 42S is 30 mm, which allows a standard 60 mm wide heat shrink sleeve to be centered on the fiber in one movement before placing it in the oven for heat shrinking. This saves the fiber splicer's valuable time.

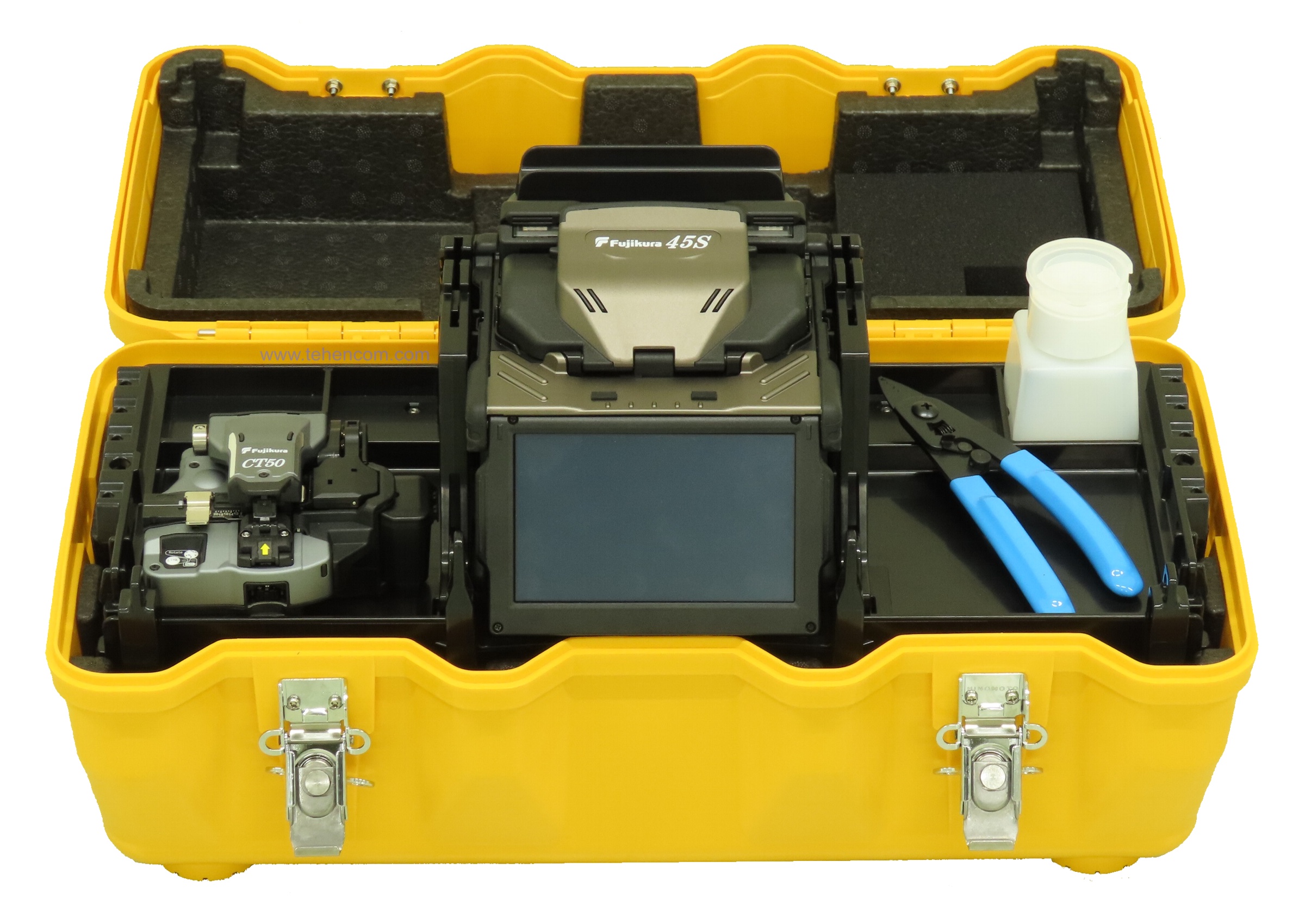

Improved case

Traditionally, all Fujikura splicers are supplied in a convenient and reliable yellow transport case. The 42S series case is designed in such a way that you can work with the splicer by simply opening the top cover of the case. This ensures normal access to the splicer and there is the possibility of placing the accessories necessary for splicing on the surface of the assembly table.

Another way to organize your workspace is to use a removable mounting table, which can be removed from the case and placed on any suitable surface. The appearance of the table with the splicer attached to it is shown in this photo.

Documentation and useful materials

-

Description and characteristics of Fujikura 42S

RU, 10 pages, 3 MB

-

Instruction manual for Fujikura 42S

EN, 117 pages, 12 MB

-

Description and characteristics of Fujikura 45S

EN, 10 pages, 2 MB

-

PC software for Fujikura 42S, 45S

EN, version 1.0.1.0, 16 MB

-

PC software instruction manual for Fujikura 42S, 45S

EN, 45 pages, 3 MB