Welding machine for access networks, PON/FTTx and SCS Fujikura 19S

Product code: 1000241

On orderAdd item to cart. Our specialist will coordinate with you the complete set, tell you the price and delivery time.

Price on request

BRIEF DESCRIPTION OF FUJIKURA 19S FIBER WELDING MACHINE

Fujikura 19S is a new model fiber optic splicer introduced by Japan's Fujikura in 2013. The Fujikura 19S model is a continuation of the line of welding machines FSM-18S (2008) and FSM-17S (2004). Like its predecessors, the Fujikura 19S is well suited for access networks, PON/FTTx, SCS, and local fiber optic links. Fujikura 19S splices any type of fiber with little loss even under harsh conditions (low temperature, extreme heat, humidity, wind), while the splicer is unpretentious and very reliable in operation. Service life, even in the most severe conditions, exceeds 10 years. Very cheap consumables: a pair of electrodes ELCT2-20A, designed for 3000 welds, costs only $60 (2 cents per weld).

The main difference between Fujikura 19S and the older model Fujikura 80S - this is a method of fiber convergence: Fujikura 19S brings the fibers together on the sheath. Otherwise, the 19S and 80S models are virtually identical: record-breaking 9 second splice and 14 second heat shrink times, fully automated wind cover, heat shrink oven and automatic fiber presses, and even more shock, shock and drop resistance - the Fujikura 19S withstands being dropped on any edge, including windshields. Authorized service located in Kyiv. If the repair takes more than 3 working days, then a replacement device is provided for the period of repair.

Main characteristics:

Alignment to the cladding of an optical fiber.

Average welding losses: 0.05 dB (single mode), 0.02 dB (multimode).

Welding time: 9 s. Heat shrink time:

14 s. Electrode resource: 3000.

The number of welding / heat shrink cycles from a standard Li-ion battery: 180.

Automatic: wind cover, heater, fiber clamps.

Arc power autotuning. Built-in video instruction.

Simultaneous viewing of the welding spot along the X and Y axes.

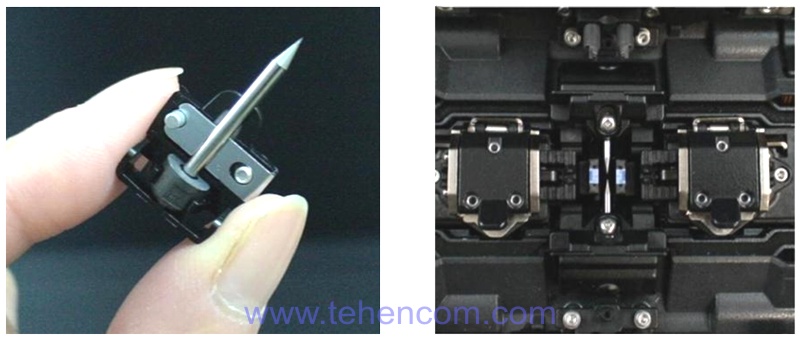

Chip length: from 5 to 16 mm. Ability to weld connectors SC, LC, etc.

Russified menu. Free firmware update via the Internet.

Operating temperature range: from -10°С to +50°С. Weight with battery: 2.5 kg.

The highest protection against dust, moisture, shock and drops.

3 years of a full factory warranty with the replacement of the device for the period of repair.

Available on special order. Recommended replacement: Fujikura 36S.

Since the Fujikura 19S fiber fusion splicer is structurally almost identical to the older 80S model and has the same excellent protection against dust, moisture, shock and vibration.

Tehencom LLC is the official distributor of the company Fujikura on the territory of Ukraine.

Fujikura Exclusive Distributor Certificate (65 KB)

When buying a set of equipment (for example welding machine+reflectometer) will receive an additional discount. We also provide professional training with the issuance of a personal certificate. All details can be found by phone: (044) 338-11-77, (097) 650-11-77, (095) 650-11-77, (093) 650-11-77.

DETAILED DESCRIPTION OF THE FUJIKURA 19S FIBER WELDING MACHINE

In 2013, Fujikura introduced three new fiber splicers at once: the older model Fujikura 80S, middle model Fujikura 19S and junior compact model Fujikura 12S.

The main difference between Fujikura 19S and the older model Fujikura 80S is a fiber convergence method: Fujikura 19S converges the fibers along the cladding, so the average splice loss is slightly higher: 0.05 dB for single mode (compared to 0.02 dB for model 80S). This is a very good result for devices of this class, so the Fujikura 19S model is excellent for access networks, PON / FTTx, SCS and local lines. Model 19S splices all types of used fibers: single mode SM (G.652/657), multimode MM (G.651), DSF (G.653), NZDSF (G.655).

A simpler method of bringing the fibers together made the 19S cheaper than the 80S.

Fujikura 19S Optical Fiber Fusion Splicer has 100 pre-configured splicing modes and 30 heat shrink modes, the parameters of which can be changed as needed. To simplify the work of the installer in the new model Fujikura 19S, the operation of the windproof cover is automated (opens and closes on its own), a heat shrink heater (opens and closes by itself) and fiber clamps (opens by itself after welding is completed). The high speed of 19S eliminates the need for an additional oven for heat shrinking KDZS, which is used in other, older devices.

In Ukraine and the CIS, welding machines of the Japanese company Fujikura have been widely used since 1989 and have proven to be extremely reliable: they work for years, cook any type of fiber in severe weather conditions, not afraid of shaking during transportation and accidental drops, and in a critical situation they can be easily and quickly serviced in authorized service center in Kyiv. But Fujikura does not stop there and continues to improve and improve equipment. The new Fujikura 19S is designed to withstand drops directly onto the windshield and shrink heater like no other device can. Also Fujikura 19S has high protection against dust and moisture and provides operation in a wide temperature range: from -10°С to +50°С.

For the convenience of users, the menu of the Fujikura 19S welding machine Russified. A detailed user manual is supplied with each machine, in addition, the welding machine itself contains a video instruction that can be viewed on the high-resolution color screen of the machine.

The new Fujikura 19S fiber splicer is an excellent solution for the construction and maintenance of access networks, PON/FTTx networks, SCS and local fiber optic lines.

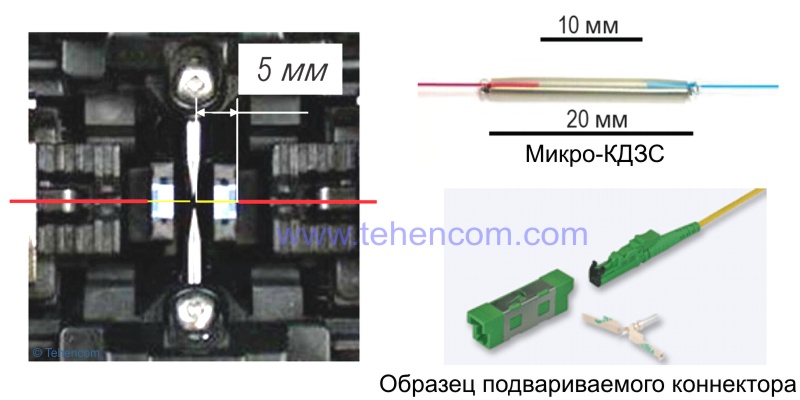

Fujikura 19S supports fiber cleavage lengths from 5mm to 16mm

The Fujikura 19S features miniature fiber landing pads that support cleavage lengths from 5mm to 16mm. A 13-16mm chip is typically used with standard 60mm SHRs, a 10-12mm chip is used with 40mm SHRs, and a minimum 5mm chip is required to work with the new micro-SHRs (20mm and 30mm) as well as for terminating fibers with Fujikura FuseConnect weldable connectors.

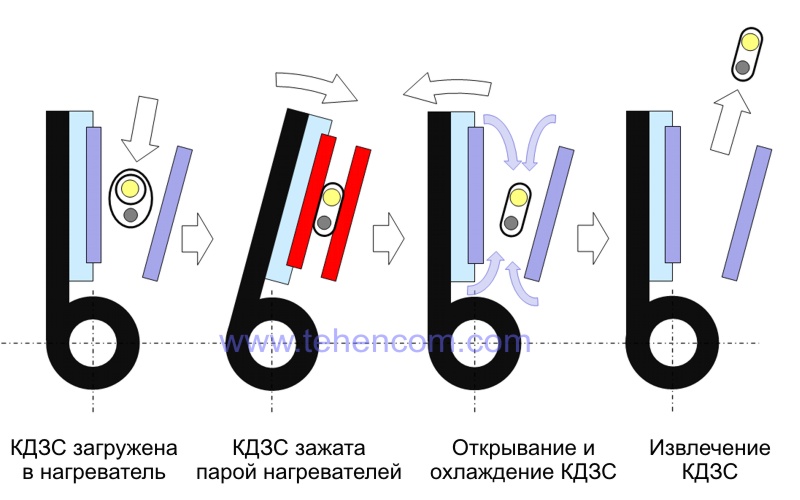

The revolutionary design of the Fujikura 19S KDZS heater and a record heat shrink time of 14 seconds

The Fujikura 19S optical fiber splicer combines a fast splicing time of 9 seconds with a record shrink time of 14 seconds. None of the welders produced in the world can achieve such speed. In order to make such fast shrinking possible, the Fujikura 19S has developed a completely new heater.

In a conventional heater, a heat-shrinkable sleeve (KDZS), together with the fiber, is placed in the heater tray, the lid is closed manually and the sleeve shrinks, after which it must be manually removed. The new model 19S heater automatically opens and closes itself when loading the CDS, and after the end of heat shrinkage and cooling, it automatically opens. It's convenient and fast. At the same time, during heating, the CDS is not located in the tray, but is tightly clamped by two heating elements, as shown in the figure. This design of the heater provides several important advantages: fast and uniform heat shrinkage of the CDS (because the sleeve is tightly attached to the heating plates), stable operation at low temperatures and strong winds (this is important,

Low cost of operation Fujikura 19S and cheap consumables

With intensive work on fiber optic welding, the availability and cost of consumables (electrodes) is important. The new Fujikura 19S model uses an improved arc power auto-tuning algorithm and now more than 2000 welds can be made on one pair of electrodes as on FSM-18S, a 3000 welds, while the electrodes themselves have not changed - standard electrodes are used ELCT2-20A. They are constantly in stock, a pair costs $60, which, in terms of the price of one weld, is only 2 cents per weld.

The Fujikura 19S uses a new high-capacity Li-ion battery BTR-09

Of the novelties that Fujikura 19S pleases with, it is worth noting the new Li-ion battery BTR-09 increased capacity. When this battery is installed in the welder, the Fujikura 19S can perform approx. 180 heat shrink welds. Also, the new BTR-09 battery does not require regular calibration.

Innovative design of the case and mounting table of the Fujikura 19S welding machine

The new Fujikura 19S case helps to protect the machine and accessories from damage, as well as organize the welder's workspace efficiently.

For ease of installation, each Fujikura 19S comes standard with a special mounting table of a new design, on which you can place the welding machine and additional tools during operation: cleaver, stripper, KDZS, etc. The removable mounting table can be used separately from the suitcase ( case) or directly inside the suitcase (without taking it out). When transporting, the table simply fits inside the case.

Compact and light weight of the Fujikura 19S welding machine

For comfortable work, the optimal dimensions of the welding machine and its weight are very important. Fujikura has kept the size of the 19S to a reasonable minimum. The overall dimensions of the Fujikura 19S welder are only 146 x 159 x 150 mm. A further reduction in the size of the apparatus would lead to a reduction in the size of the screen and, as a result, to a deterioration in the convenience of viewing the image of the fibers and the splicing site. Machine weight with power supply ADC-18 from a 220 V network is 2.3 kg, and with a battery BTR-09 only 2.5 kg.

Specifications of Fujikura 19S Automatic Fiber Splicer

Three options for the delivery of the Fujikura 19S welding machine

Fujikura 19S Kit-A Plus (the most complete set):

- Fujikura 19S welding machine

- automatic cleaver CT50

- wall adapter/charger adapter ADC-18

- accumulator battery BTR-09

- battery charging cord DCC-18

- power cord for connecting to a car cigarette lighter DCC-12

- power cord for connecting to an external battery (with alligator clips)DCC-13

- additional holders for pigtails in free buffer CLAMP-S70D

- spare electrodes (2 pairs)ELCT2-20A

- ACC-15 AC power cord

- CC-30 hard case

- USB-01 USB cable

- SL-01 BCD fitting tool

- AP-01 alcohol dispenser

- SC-01 screwdriver

- CD with Data Connection software and training videos

- quick reference guide

- warranty card for 3 years warranty (2 years factory warranty + 1 year from Tehencom)

Fujikura 19S Kit-A Standard (simpler cleaver):

- Fujikura 19S welding machine

- automatic cleaver CT08 with an additional platform for installing fibers

AD-10-M24

- wall adapter/charger adapter ADC-18

- accumulator battery BTR-09

- battery charging cord DCC-18

- spare electrodes (1 pair)ELCT2-20A

- ACC-15 AC power cord

- CC-30 hard case

- USB-01 USB cable

- SL-01 BCD fitting tool

- AP-01 alcohol dispenser

- SC-01 screwdriver

- CD with Data Connection software and training videos

- quick reference guide

- warranty card for 3 years warranty (2 years factory warranty + 1 year from Tehencom)

Fujikura 19S Standard Kit (without cleaver):

- Fujikura 19S welding machine

- mains/charger adapter ADC-18

- accumulator battery

BTR-09

- battery charging cord DCC-18

- spare electrodes (1 pair)ELCT2-20A

- ACC-15 AC power cord

- CC-30 hard case

- USB-01 USB cable

- SL-01 BCD fitting tool

- AP-01 alcohol dispenser

- SC-01 screwdriver

- CD with Data Connection software and training videos

- quick reference guide

- warranty card for 3 years warranty (2 years factory warranty + 1 year from Tehencom)

Options and accessories for the Fujikura 19S welding machine

Removable holders Fujikura FH-60 series for different types of fiber buffer:

- FH-60-250 (for bare fiber 0.25 mm)

- FH-60-900 (for pigtails with 0.9 mm sheath)

- FH-60-DC250 (for 0.25 mm bare fiber with DropCable jacket)

- FH-FC-20 (for patch cords in 2 mm sheath)

- FH-FC-30 (for patch cords in 3 mm sheath)

- FH-60-LT900 (for pigtails in free buffer 0.9 mm)

Documentation

Description of Fujikura 19S fiber splicer (in Russian) (2 pages; 310 KB)

What is the difference between Fujikura cleavers? Which model to choose? Questions and answers